- HOME

- > Product

- > Measurement Instruments

- > Impedance Analyzer

- > Impedance Analyzer ZA57630 : Features

Impedance Analyzer

Impedance Analyzer

ZA57630Features

A diverse array of functions to suit any application!

Highly repeatable and accurate measurements.

Accurate assessments conducted under actual usage

conditions.

Electronic parts and materials may indicate varying

characteristics at different measurement frequencies or when different signal levels are

applied. To assess true characteristics, it is important to take measurements under

actual operating conditions by sweeping the frequency, AC amplitude and DC bias.

Features

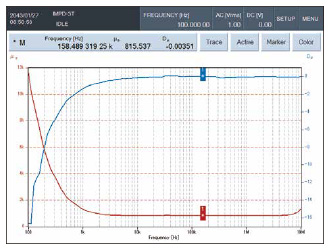

- ● SWEEP

- ● SETTING MEASUREMENT AND OTHER CONDITIONS

- ● MEASUREMENT RANGE

- ● MEASUREMENT DELAY FUNCTION

- ● AUTOMATIC HIGH DENSITY SWEEP

- ● ERROR CORRECTION FUNCTION

- ● MARKER CONTROL

- ● SEQUENCE MEASUREMENT FUNCTION

- ● GRAPH DISPLAY

Useful Function

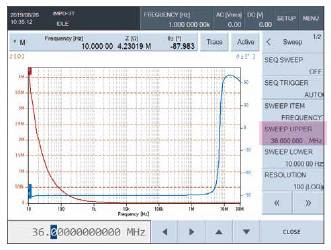

SWEEP Frequency, AC amplitude, DC bias, zero span

AC amplitude sweep

Frequency sweep

DC bias sweep

Zero span

Takes measurements under fixed conditions without changing frequency, AC amplitude or DC bias parameters, to observe the change in characteristics over time (horizontal axis: time)

● Also capable of spot measurements

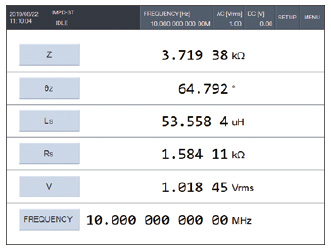

Measures a fixed frequency, AC amplitude and DC bias, and displays the results as numerical values. Up to 6 items can be configured.

For measurements on production lines

SETTING MEASUREMENT AND OTHER CONDITIONS

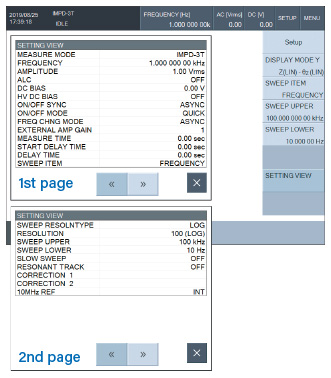

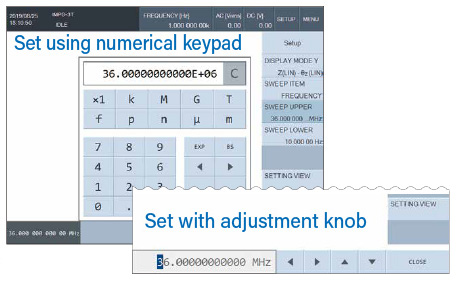

Settings intuitively on a single screen

Setting items (SETTING VIEW)

Graph axis setting

Frequency settings

MEASUREMENT RANGE

Auto range

Takes measurements by setting the optimal measurement range automatically while monitoring measurement results. This is effective when there are significant changes in measurement data.

Fixed range

The measurement range is fixed, which prevents discontinuity (steps) in the measured value caused by changes in the range.

MEASUREMENT DELAY FUNCTION

If sweep parameters such as frequency or AC amplitude are changed while

sweep is in progress, incorrect measurement results can be generated due to transient

response.

The time until measurements start after parameters are changed can be delayed.

Two delay types are available: “Measurement start delay” and “Measurement

delay”

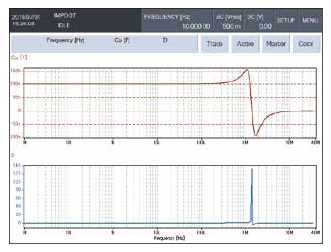

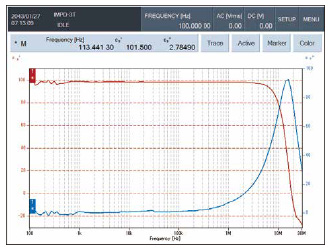

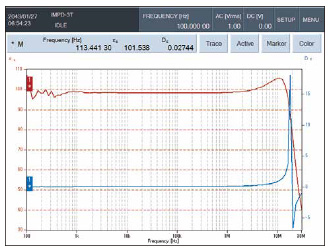

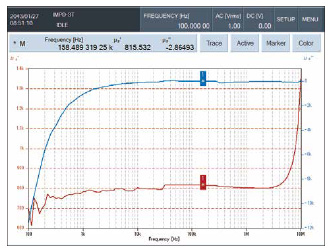

AUTOMATIC HIGH DENSITY SWEEP

This function automatically raises the frequency density only for sections

where the measurement data changes suddenly during frequency sweep measurements.

During resonance characteristic measurements of devices like piezoelectric vibrators and

crystal oscillators, this function is useful.

ERROR CORRECTION FUNCTION

Corrections to causes of measurement errors, for accurate assessments.

To conduct accurate measurements, various measurement error causes such as residual impedance and cable length must be corrected properly.

Open correction

Reduces errors caused by residual admittance

Short correction

Reduces errors caused by residual impedance

Load correction

Corrects deviations from true values using samples with known values as standard impedance

Port extension

Corrects phase errors due to transmission delay time when using long cables

Slope compensation

Removes the effect of potential fluctuation wave included in the measurement signal. Effective for measurements of samples such as batteries with potential changes due to charging and discharging

Equalizing

Measures the frequency characteristics of sensors, cables and other externally connected measurement devices, and corrects the amount of error of those measurement devices

Input weighting

Corrects the probe attenuation or pre-amp gain

Self-calibration

Self-calibrates errors

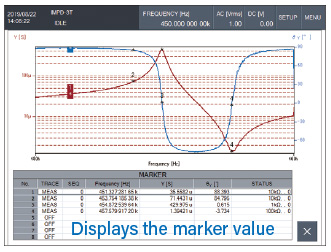

MARKER CONTROL

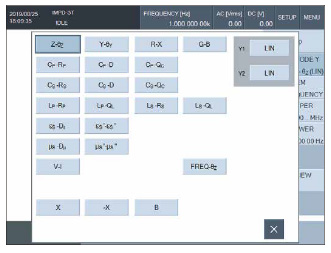

Reads the measurement values for X, Y1 and Y2 shown on the graph.

Up to 8 markers can be used.

Δ Marker

Displays the difference from the standard marker (Marker 1)

ΔTRKG Marker

Displays the difference in the same way as the difference marker. When marker 1 is moved, it moves while keeping the difference in the sweep value constant.

Marker search function

Automatically searches points that match the setting conditions

SEQUENCE MEASUREMENT FUNCTION

Multiple measurement conditions are set in advance, and this function

conducts measurements in order under those conditions.

The sweep range can be split into segments, with measurements taken under different

conditions for each segment range.

Enables efficient measurements of multilayer ceramic capacitors (MLCC), and other devices

with characteristics that vary with voltage.

GRAPH DISPLAY

SINGLE/SPLIT display

Select from “SINGLE” with one graph shown per screen, or “SPLIT” with two graphs shown top and bottom

Phase display control

±180°, 0° to +360°, −360° to 0°, UNWRAP (continuous display), 360° shift, aperture (group delay characteristics)

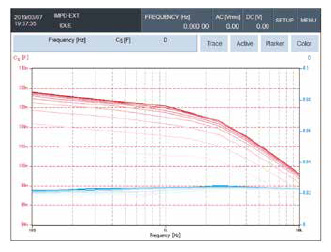

Trace control

Allows overwriting of measurement data trace (MEAS) and up to 8 reference data traces (REF)

Auto store

After sweep measurement is completed, this function automatically copies the MEAS trace to the REF trace.

● SPLIT display

● Auto store

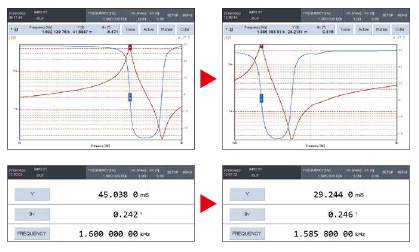

RESONANT FREQUENCY TRACKING FUNCTION

During measurement of samples with resonance, this function automatically tracks the measurement frequency with the sample resonant frequency. Measurement can always be conducted to match the resonant frequency. A convenient function for continuous measurements close to the resonant frequency of piezoelectric devices.

Resonant frequency changes (1.6 kHz to 1.5858 kHz),

tracks automatically

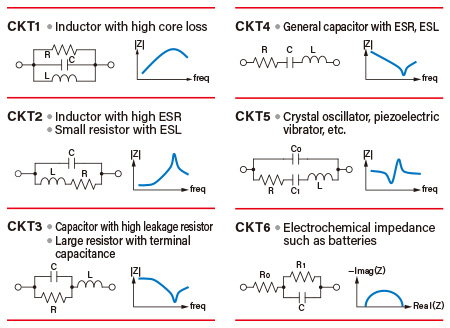

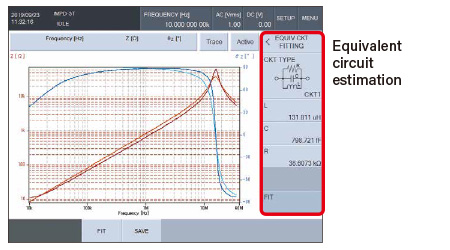

EQUIVALENT CIRCUIT ESTIMATION FUNCTION

A function that determines the LCR element value (values for impedance,

electrostatic capacitance and resistance) by applying the impedance characteristics acquired

with frequency sweep measurements to equivalent circuit models.

The following 6 models are included.

Equivalent circuit model

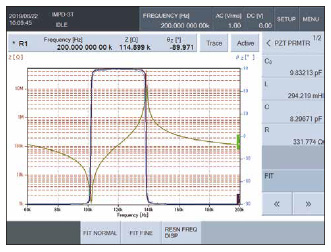

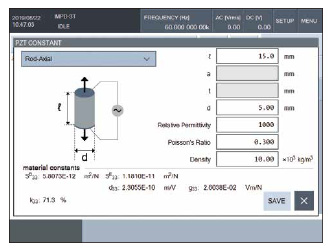

PIEZOELECTRIC CONSTANT CALCULATION FUNCTION

Function that measures frequency-impedance characteristics of piezoelectric ceramics to calculate the electromechanical coupling factor, piezoelectric constant and others.

∗JEITA standard-compliant method “EM-4501A Electrical test methods for piezoelectric ceramic vibrators”.

Measurement results

Constant calculation

RELATIVE PERMITTIVITY MEASUREMENT

Sample dimensions and other information is set in advance, to calculate and display the complex relative permittivity from impedance measurement results (Cp, Rp).

● Relative permittivity εs

● Relative permittivity, real εs’

● Relative permittivity, imaginary εs”

● Loss ratio Dε

εs’−εs”

εs−Dε

RELATIVE MAGNETIC PERMEABILITY MEASUREMENT

Sample dimensions and other information are set in advance, to calculate and display the complex relative magnetic permeability from impedance measurement results (Ls, Rs).

● Relative magnetic permeability µs

● Relative magnetic permeability, real µs’

● Relative magnetic permeability, imaginary µs”

● Loss ratio Dµ

µs’−µs”

µs−Dµ

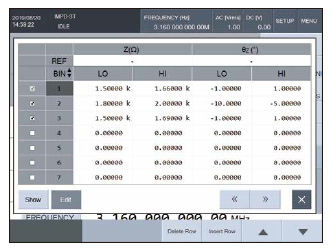

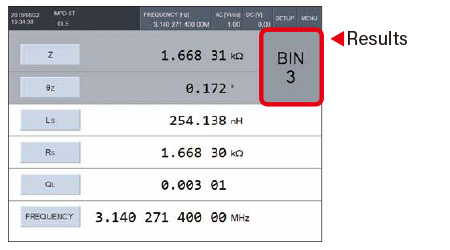

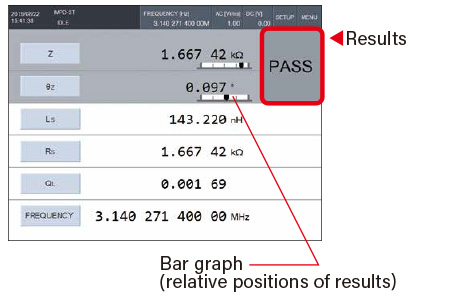

COMPARATOR/HANDLER INTERFACE Ideal for production lines!

Measurement up to 0.5 ms/point to shorten

takt time

Also with parts selection function!!

The comparator is a function that allows samples to be sorted or passed/rejected by setting the criteria range in advance based on measurement results.

Comparator setting screen

Bin sorting

Sorts results in up to 14 categories.

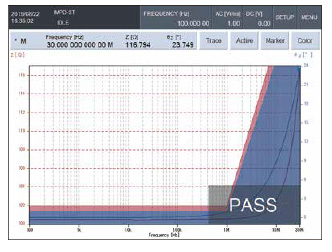

Limit sorting

Determines pass/reject based on the set range.

Zone sorting

Determines pass/reject based on sweep measurement results in two-dimensions, X axis (sweep parameter) and Y1, Y2 axes (measurement results).

Handler interface

The comparator criteria results can be output to the handler interface connector. Connect a parts handler to create an automated parts sorting system.

EXTERNAL REFERENCE CLOCK

An external 10 MHz clock signal can be used as

the reference clock.

Using a reference clock with a higher precision than the internal reference clock helps to

improve the measurement frequency accuracy and stability.

The use of a reference clock

common with other devices also allows for the same frequency accuracy.

Mounted on rear panel

MEMORY CONTROL

Measurement conditions and measurement data can be saved and loaded onto the internal memory or USB memory storage.

● Electrochemical impedance characteristics measurements

Functions cover a range of measurements of electrochemical impedance characteristics, such as battery internal impedance measurements.

- ● Ultra-low frequencies from 10 µHz

- ● Phase slope compensation

function to limit measurements being affected

by potential changes due to charging and discharging - ● 0° SYNC function changes

the measurement frequency by 0° phase,

for zero charge transfer before and after measurements.